Product Development/Production Technology

1.Product Development

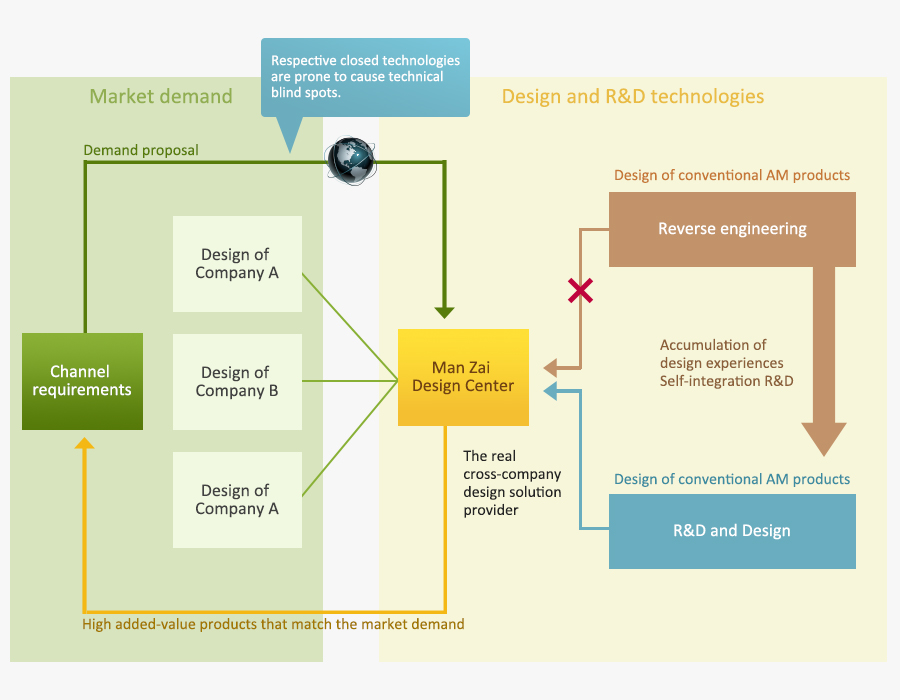

Man Zai believes that for product development, in addition to meticulous development/validation procedures carried out jointly with OEM/ODM customers, unconventional innovation shall be adopted for AM products by leveraging design experiences of those major manufacturers, with the expectation of becoming a cross-company design-solution provider.

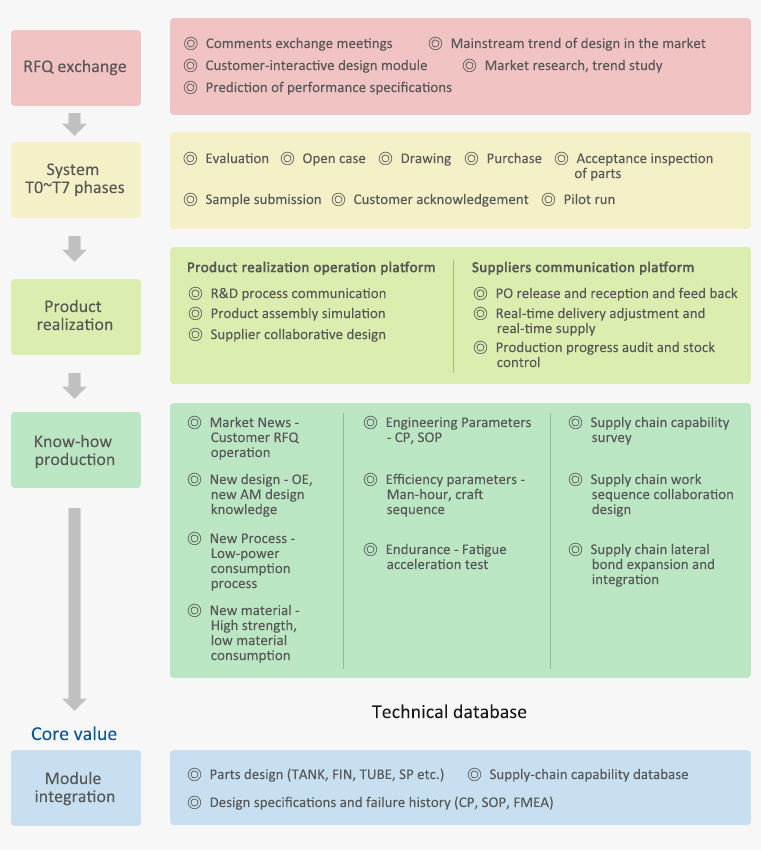

Product development procedure of Man Zai covers communication of customer-end requirements, development implementation, product realization, to know-how production and technical database integration. Via systematic thinking and logic, we endeavor in providing the core value of technical elevation so as to offer the customer with products having the in-time delivery, the best quality and the most competitive price in a continuous manner to maintain sustainable competitiveness.

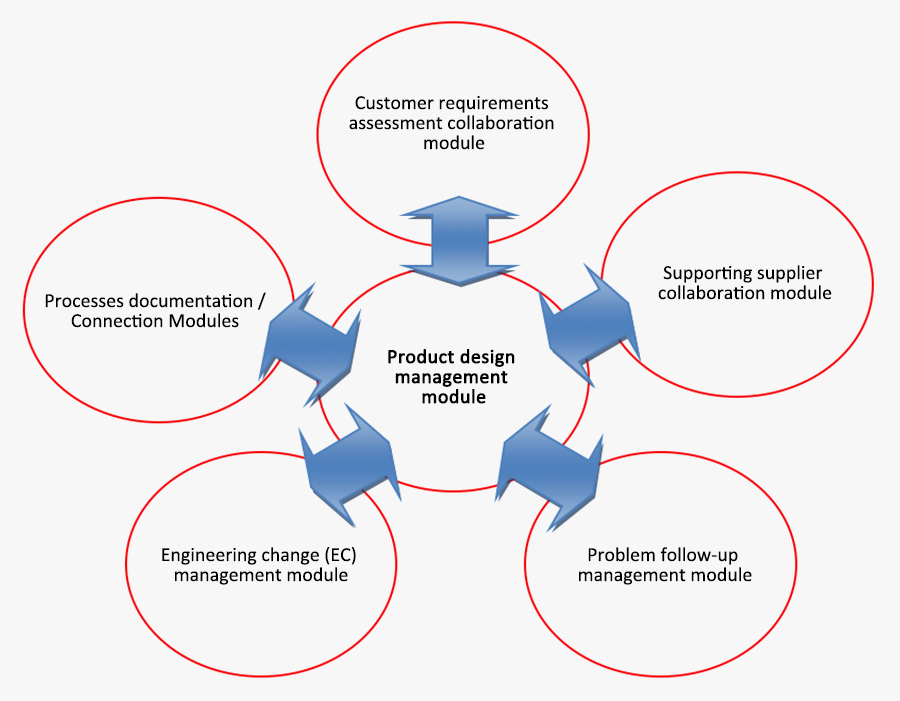

Man Zai introduced PLM (Product Life Cycle Management) platform in 2012 to realize production development principles, thereby integration of customer requirements assessment, supplier, product design management, problem follow-up, engineering changes (EC) and documentation of procedure management are implemented to achieve integrated results of product design and development via this IT platform

2.Production Technologies

| Process | Furnace | Extrusion | Punching Press | Assembly | Brazing Furnace | Leakage Test |

| Existing equipment | Aluminum ingot melting furnace | Double cylinder extrusion machine 800T extrusion machine |

250T continuous punch Pneumatic punch Conventional punch |

Fully automatic assembly machine Semi-automatic assembly machine Manual assembly machine |

Brazing Furnace 1 Brazing Furnace 2 Brazing Furnace 3 |

Helium detector Differential pressure leak detector |

|

|

|

|

|

|

|

| Technical advantages | Aluminum alloy formulation Provision of self-made raw material for extrusion |

Aluminum extrusion production, provision of parts for self-use and for sale | Versatile molds for parts processing; with 90%+ self-provided ratio | Comprehensive specifications corresponding with flexible production of versatile products | Tunnel type brazing provide stable temperature control and weld quality | Final inspection before delivery for ensured product quality |